Case Study: Automating Hydraulic Testing Systems.

Revolutionizing Air Control Valve Testing Through Automation

Executive Summary

This case study examines how Embedos Engineering’s specialized automation solution transformed the testing processes for Air Control Valves (ACVs) at a leading hydraulic equipment manufacturer in India. The implementation of the ACV Testing Automation System enhanced testing precision, increased operational efficiency, and improved quality assurance protocols, resulting in significant time savings and more reliable product performance.

Client Profile

A prominent hydraulic systems manufacturer based in Mumbai, India, specializing in the production of high-performance hydraulic equipment for commercial vehicles and industrial applications. The company has established itself as an industry leader with a focus on innovation and quality control.

About Embedos Engineering

Embedos Engineering LLP, headquartered in Mumbai, is a pioneering force in End-to-End Industrial IoT Solutions. The company specializes in developing cutting-edge smart devices and cloud-based web solutions tailored for remote monitoring, control, and Industry 4.0 applications. Embedos Engineering’s core mission is to facilitate the seamless digitization of existing factory and process automation systems, enabling businesses to embrace the future of connectivity and efficiency.

Challenge

Testing Complexity and Reliability Issues

The client faced several critical challenges in their ACV testing processes:

- Manual Testing Inefficiencies: Traditional manual testing methods for Air Control Valves were time-consuming, labor-intensive, and prone to human error.

- Inconsistent Test Results: Lack of standardization in testing procedures led to variable outcomes and difficulty in establishing reliable quality benchmarks.

- Limited Data Collection: The existing process provided minimal documentation of test parameters and results, hindering quality tracking and continuous improvement initiatives.

- Scalability Concerns: As production volumes increased, the manual testing approach became a bottleneck in the manufacturing pipeline.

Solution

Embedos ACV Testing Automation System Work Bench

Embedos Engineering developed an end-to-end automation solution to address these challenges, consisting of:

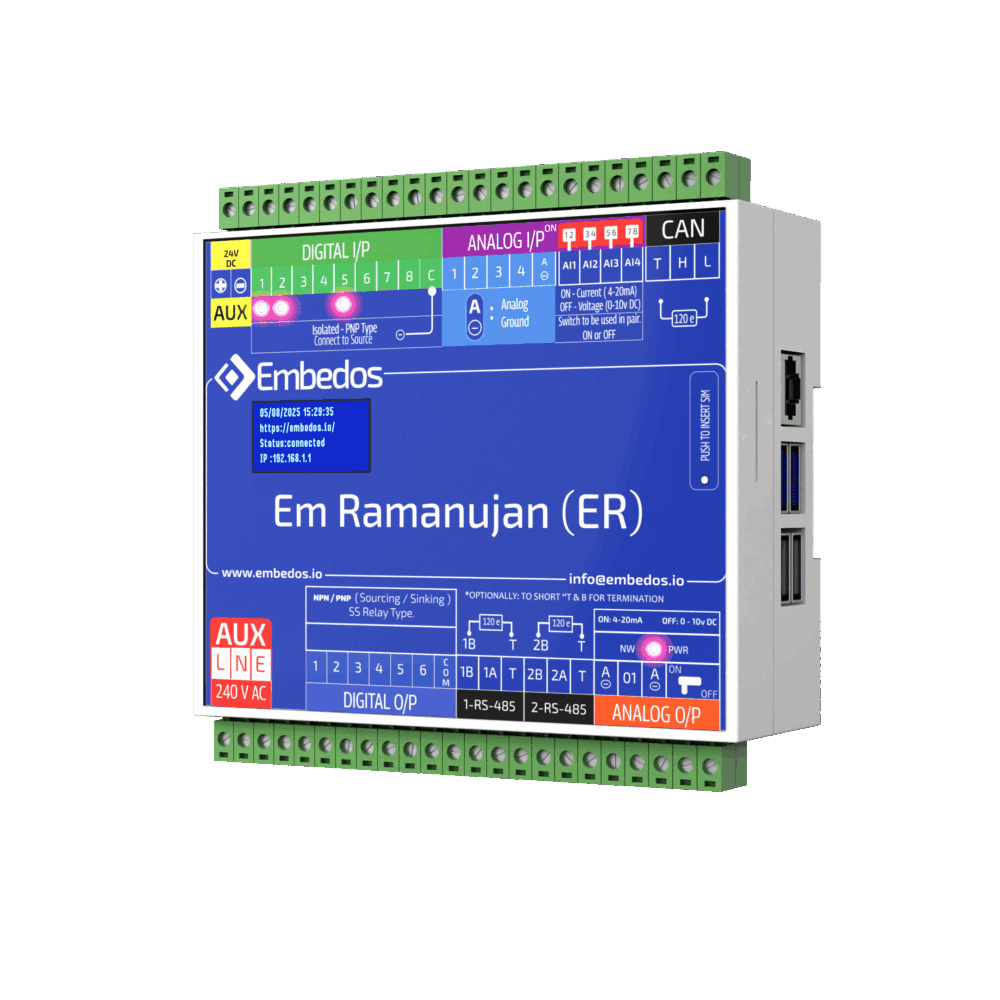

Hardware Components

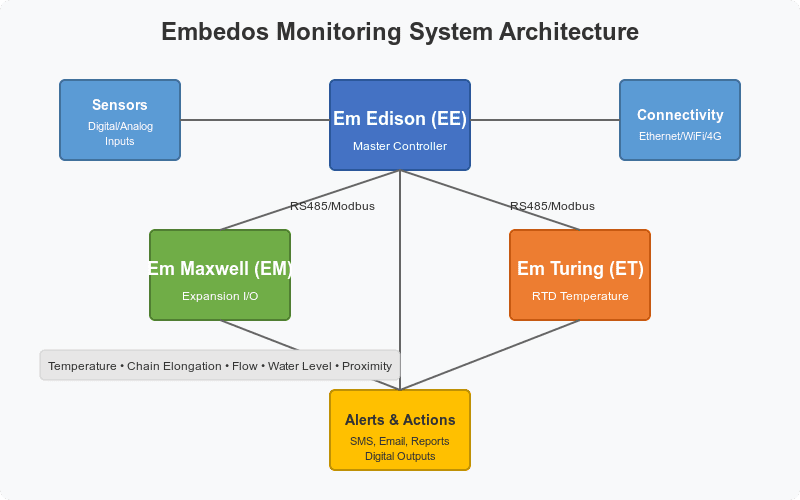

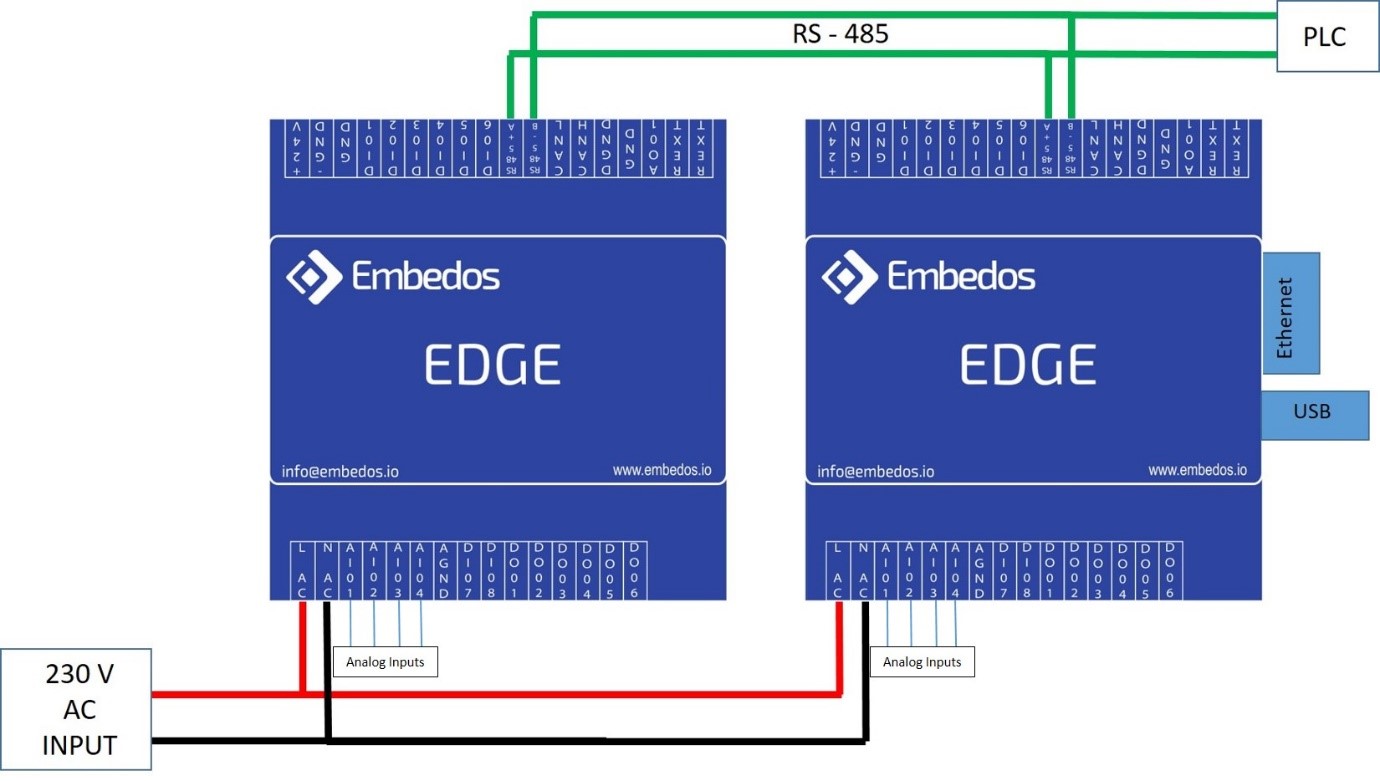

- Embedos Edge Devices: Dual-configuration setup with master and slave devices to control and monitor testing operations.

- Digital and Analog I/O Configuration: Comprehensive input/output mapping for precise control and data acquisition.

- Pressure Transducers: Four strategically positioned sensors (PT1-PT4) to measure pressure at critical valve positions.

- Solenoid Valves: Automated control of testing media flow and pressure application.

Software Elements

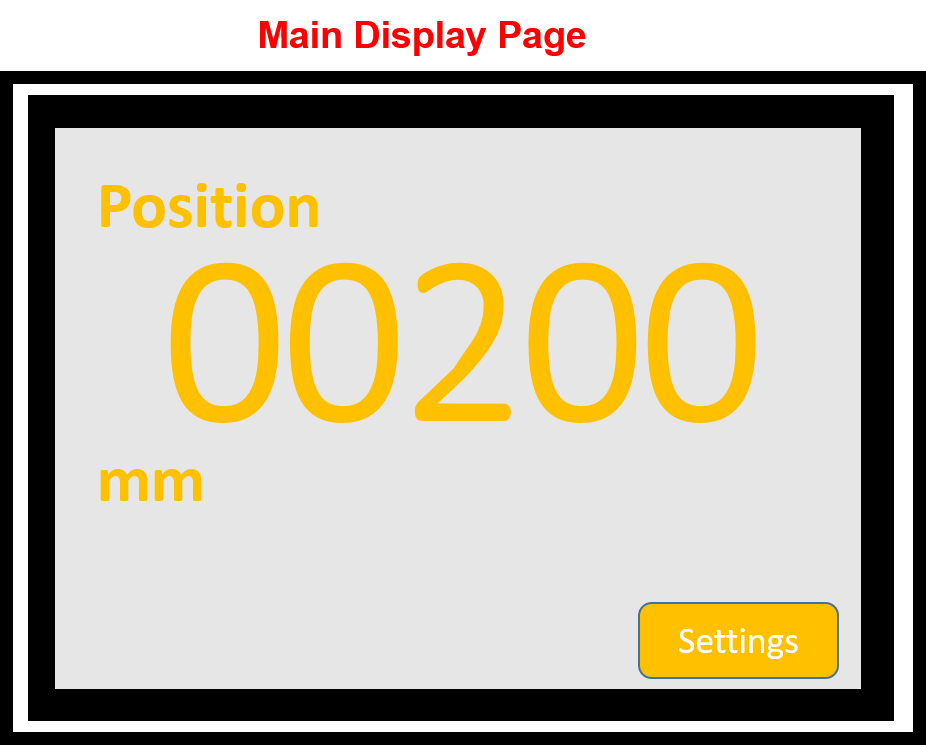

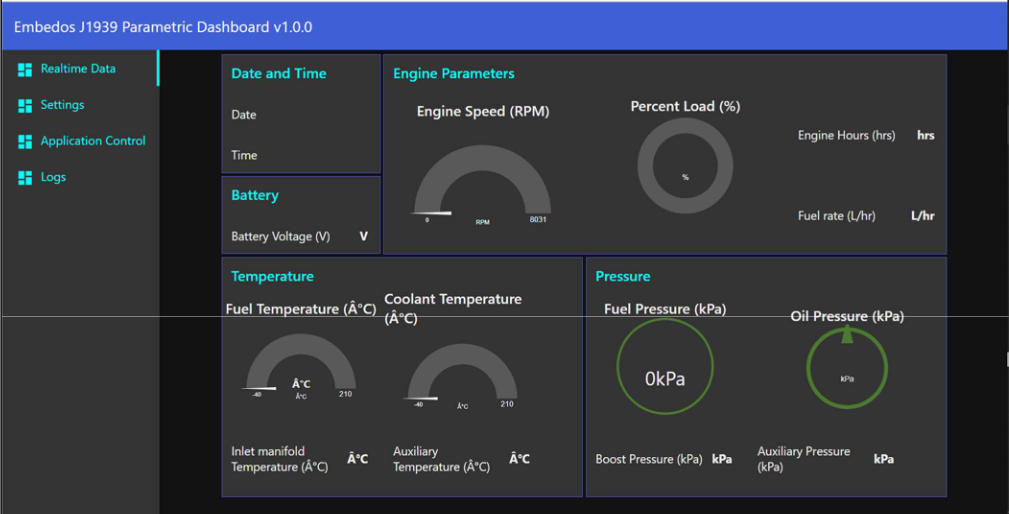

- Embedos Real-time Dashboard: Intuitive interface displaying live sensor values, test statuses, and operational parameters.

- Configuration Management Portal: User-friendly controls for adjusting critical test parameters including:

- Flushing time

- Hold time

- Delay time

- Error point thresholds

- Automated Test Sequencing: Predefined test cycles with position control for Initial, PTO, Tipping, and Lowering positions.

- Comprehensive Reporting System: Automated generation of test reports with options for PDF, CSV, and Excel formats.

Implementation Process

Phased Deployment Approach

The implementation followed a structured methodology developed by Embedos Engineering:

- Hardware Installation: Setting up the Embedos Edge devices, sensors, and control mechanisms according to detailed electrical wiring diagrams.

- System Configuration:

- Mapping analog inputs to required ranges through the Embedos configuration interface.

- Configuring network settings for connectivity.

- Setting up real-time clock parameters.

- Software Setup:

- Installation of the Embedos control application accessible via port 3001.

- User authentication system implementation.

- Dashboard and reporting interface configuration.

- Testing Protocol Development:

- Creating standardized testing sequences.

- Establishing pass/fail criteria.

- Implementing safety measures including emergency stops and collision protection.

- User Training:

- Hands-on training for operators and maintenance personnel.

- Documentation and reference materials development.

Results

Transformative Operational Improvements

The implementation of the Embedos ACV Testing Automation System delivered substantial benefits:

Efficiency Gains

- Testing Time Reduction: Standardized testing cycles significantly decreased the time required per valve.

- Automated Documentation: Elimination of manual record-keeping freed up valuable technician time.

Quality Improvements

- Consistent Test Parameters: Standardized testing conditions across all valve types.

- Enhanced Leak Detection: Precise pressure measurements at four distinct positions improved defect identification.

- Data-Driven Quality Control: Comprehensive test reports facilitated trend analysis and quality improvements.

Operational Benefits

- Dual Mode Functionality: Production and maintenance modes provided operational flexibility.

- Remote Monitoring Capabilities: Embedos network connectivity enabled off-site supervision and analysis.

- Historical Data Analysis: Archived test results supported continuous improvement initiatives.

Key Features and Innovations

Advanced Testing Capabilities of the Embedos Solution

The system incorporated several innovative elements:

Multi-Position Testing

The Embedos solution enabled thorough testing at four critical valve positions:

- Neutral (Initial) Position

- PTO Position

- Tipping Position

- Lowering Position

Intelligent Test Sequencing

Automated progression through test phases with built-in safety protocols to prevent equipment damage.

Customizable Parameters

Adjustable settings allowed for optimization across different valve models and testing requirements.

Comprehensive Data Visualization

Embedos Engineering’s real-time displays of:

- Live sensor values

- Test duration

- Pressure differentials

- Pass/fail status indicators

Integration with External Systems

The Embedos ACV Testing Automation System seamlessly integrates with separate systems, functioning as the central control unit for orchestrating and monitoring the entire testing process. This integration enhances the overall automation capabilities and ensures smooth operation across different system components.

Future Directions

Pathway to Further Enhancement

The successful implementation has opened opportunities for additional improvements with Embedos Engineering:

- Integration with Manufacturing Execution Systems: Connecting the Embedos testing platform with broader production management systems.

- Predictive Analytics: Applying machine learning to test data to predict valve performance and potential failures.

- Remote Troubleshooting Capabilities: Enhanced Embedos connectivity features to allow expert intervention from offsite locations.

- Expanded Test Parameters: Additional sensing capabilities to measure temperature, flow rates, and other variables.

Conclusion

The Embedos ACV Testing Automation System represents a significant advancement in hydraulic component quality assurance.

By replacing manual testing procedures with Embedos Engineering’s automation solution, the client has achieved remarkable improvements in testing precision, operational efficiency, & data management.

This case study demonstrates how Embedos Engineering’s targeted technological intervention in specialized manufacturing processes can yield substantial benefits in product quality, operational efficiency, and competitive advantage. The solution not only addressed immediate testing challenges but established a foundation for continuous improvement and further technological integration in the Industry 4.0 landscape.

For more information about Embedos Engineering’s solutions, visit www.embedos.io or contact info@embedos.io.

Grab Your Copy Of The Case Study, Now!

Looking for End to End Industrial Automation & IoT Solutions?