Tank Fill Control – Tank Level Monitoring!

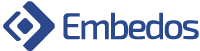

1) The Embedos EB Series ( EM Bose ) calcuates the volume of the liquid in the tank & displays its level. The calculation is done based on the inputs from a Pressure sensor that is mounted at the bottom of the tank.

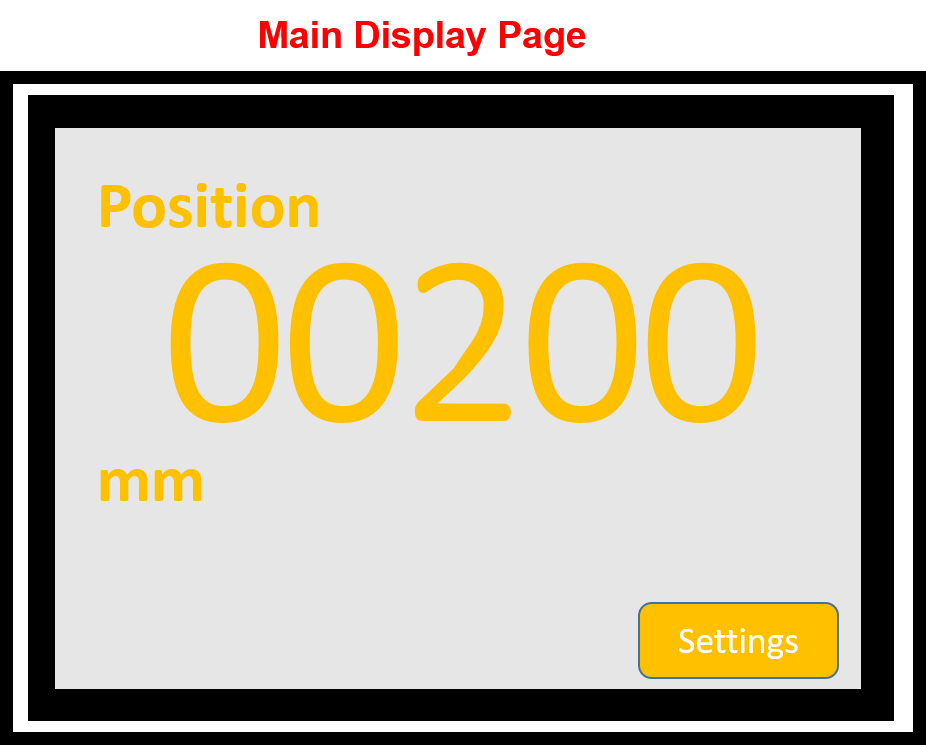

2) Em Bose displays real time values & level of the tank with a view of set points or Threshold Limits between which the liquid of interest should remain.

3) If the Liquid crosses either of the two setpoints, Em Bose (EB)sets of a relay which is connected to a high wattage Industrial Lamp ( Bulb ) to indicate that the threshold has been crossed. Also, the device has a buzzer that goes off on the crossing.

4) The buzzer can be physically acknowledged or can be disabled based on choice of the operator.

5) Threshold Crossing alerts are given for shop floor / On Field Operators to understand that the set point has been breached and thus to take further necessary action.

6) Em Bose (EB) can work with changing densities of liquids as in – liquids with different densities can be filled in the tank at a time, and the device internally calculates volume of the liquid based on relative density of the liquid.

Example: At a time, only one liquid can be filled. Since water has a different density than Oil, Milk,syrup & wine, no additional changes are to be done with the measuring equipment. Em Bose will internally handle all densities, calculate the liquid of Interest’s Volume and accordingly give us the desired Liquid level on the Touchscreen display.

7) Em Bose can be used for Vertical Tanks & Horizontal tanks.

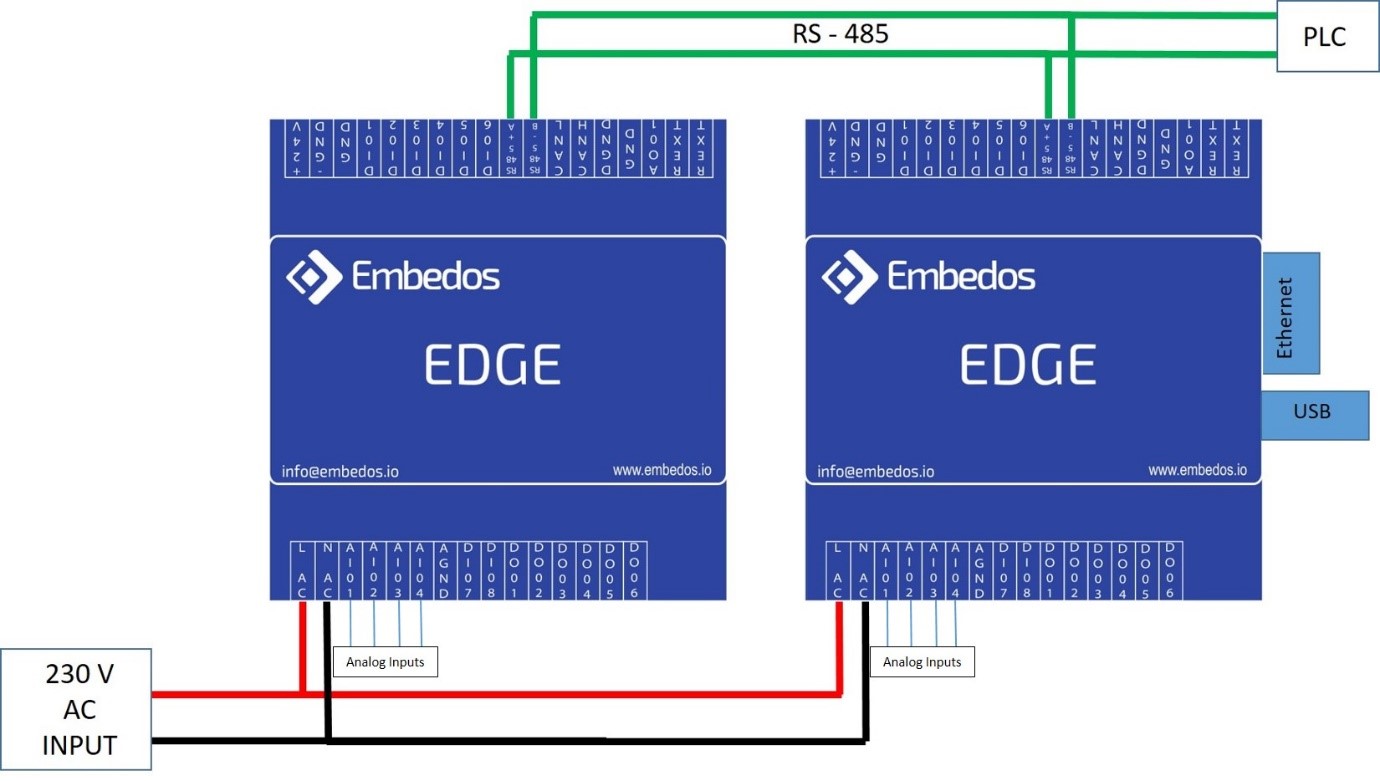

8) Em Bose (EB) consists of a Wifi interface that can be used to transmit data and receive Over the Air ( OTA ) updates if there is a requirement to upgrade the application over the internet.

9) If not a pressure sensor, a Distance / level sensor can be used to directly detect the level of the tank. But in this senario, the relative density algorithm will not work on these sensors. Additional development may have to be done to achieve this. It will not work because Density is a metric of weight and can be calculated by how much force the liquid exherts per unit area also called pressure.

10) Thus any industry that uses a tank and wants to display tank levels. So the dairy industry, or Fruit Juice manufacturers, or a wine brewery or even building water tanks can use this solution.

This is a tested and heavily deployed Industrial solution.

Looking for End to End Industrial Automation & IoT Solutions?