Some manufacturers may believe that their data is less secure if it is stored off-premises in the cloud, as opposed to being kept locally.

However, studies have shown that the majority of security issues are a result of problems with in-house processes, rather than the cloud itself.

There are several reasons why some manufacturers may not be using cloud computing.

One unfortunate reason is a lack of understanding of the technology and its capabilities.

Manufacturers may be hesitant to adopt something that is unfamiliar to them, especially if they have been successful using traditional methods.

Cost can also be a factor, as some manufacturers may believe that cloud computing is too expensive for their business.

However, many cloud providers offer pay-as-you-go models, which can be more cost-effective for #manufacturers, especially when compared to the costs of maintaining and upgrading on-premises systems.

Finally, some manufacturers may be resistant to change, and may be hesitant to adopt a new system that would require them to change the way they work.

They may see this as a disruption to their operations, and may not see the benefits of cloud computing as outweighing the costs.

Manufacturers who have not yet adopted cloud computing may be hesitant to do so for a variety of reasons. Some of the most common reasons include:

- Familiarity with traditional methods: Long-standing businesses may be reluctant to move away from the familiar ways of working that have been successful for them in the past.

- Resistance to change: The adoption of new technology often requires a change in the way a business operates, which can be uncomfortable for some manufacturers.

- Concerns about security: Some manufacturers may be concerned about the security of their data if it is stored off-premises in the cloud, rather than being kept locally.

- Lack of understanding of the technology: Manufacturers who are not familiar with cloud computing may not understand its capabilities and may be hesitant to adopt it.

- Cost: Some manufacturers may believe that cloud computing is too expensive for their business.

However, despite these concerns, there are several reasons why manufacturers should consider adopting cloud computing.

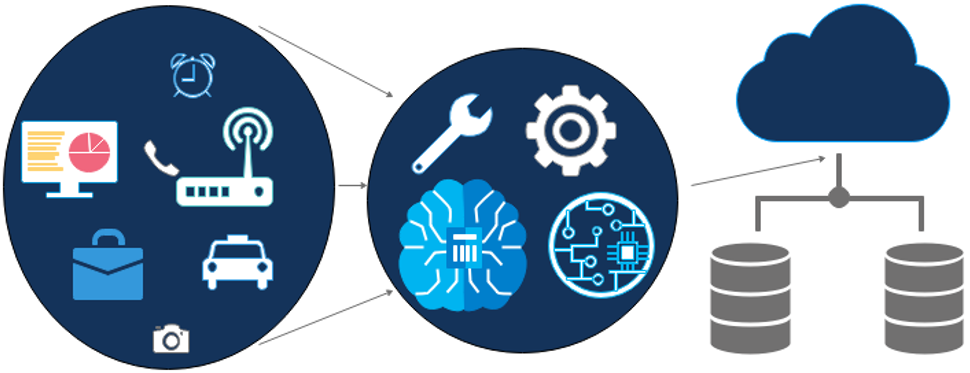

One of the main benefits is the ability to access and analyze data in real-time, which can help to improve efficiencies and make better-informed business decisions.

Additionally, cloud computing can help to reduce the costs of maintaining and upgrading on-premises systems. Furthermore, many cloud providers offer built-in security features that can help to protect data from external threats.

Are Security risks too high?

The perception that the cloud is less secure than storing data locally is a common misconception.

Many manufacturers are concerned about the security risks of storing their business-critical data off-premises, and it’s understandable that manufacturers want to ensure that their data is kept safe.

However, a study by Scalar found that almost 90% of security issues are a result of problems with in-house processes rather than the cloud itself.

This belief that the cloud is insecure may have originated from the newness of the technology, as with any new development, issues can arise.

However, the cloud’s security has evolved and improved over time, and with continued development, security measures have increased significantly.

Unlike manufacturers who have to source industry experts and bring the burden of IT security in-house, cloud providers specialize in IT security as it’s their core business.

They invest heavily in security measures to ensure that their clients’ data is safe.

This means that manufacturers can benefit from the expertise of dedicated security professionals, rather than having to rely on in-house IT teams who may not have the same level of knowledge or resources.

In conclusion, while the perception that the cloud is less secure than storing data locally is a common misconception, cloud providers specialize in IT security and have invested heavily in security measures to ensure that their clients’ data is safe.

This can provide manufacturers with access to expertise and resources that might not be available to them in-house, which can help to ensure the security of their business-critical data.

The Misconception!

The belief that a new technology will be around soon and it’s not worth investing in is a common misconception when it comes to cloud computing.

Cloud computing has proven to be a valuable technology for manufacturers, and it’s here to stay.

Using software as a service (SaaS) through the cloud provides manufacturers with the advantage of having the software updated automatically, without the burden of having to do it themselves.

This ensures that the software is always up-to-date and at the cutting edge of the industry, which can provide a competitive advantage.

Another benefit of using cloud computing is the flexibility it provides.

As the technology and its capabilities continue to evolve, manufacturers can take advantage of new features and functionalities without having to invest in new hardware or software.

Additionally, the cloud allows manufacturers to store and access their data from anywhere, at any time, which can improve collaboration and communication within the organization.

This can lead to more efficient processes and better decision-making.

The cloud is no longer a new technology and it’s here to stay.

It offers numerous possibilities and is fast becoming the foundation of how businesses operate. By using cloud computing, manufacturers can take advantage of its capabilities, reduce costs and improve their competitiveness.

The Cost of Cloud Computing!

When new technology emerges to the market, the natural association is that new equals expensive. However, as cloud software has proven time and time again, the cost-savings are in-fact generous.

As a form of SaaS, the cost of expensive software upgrades, expensive hardware and product licenses are eliminated, giving you more available cash to invest across your business.

Likewise, a third party takes the IT management aspect from your businesses, reducing the need for specialist IT skills.

One survey found that cloud-based manufacturing software can actually reduce costs by up to 54%, refuting any pre-existing views about costs.

Whether it’s reducing the need for highly skilled team members or improving operational savings across your business, the cloud presents numerous ways for manufacturers to enjoy greater efficiencies across their business.

Building trust into cloud computing!

Building trust into cloud computing is crucial for businesses as they transition their IT services to the cloud.

- Security: Ensuring that the cloud provider has robust security measures in place to protect the data and systems from unauthorized access, breaches, and attacks.

- Compliance: Making sure that the cloud provider’s services comply with relevant laws, regulations, and industry standards.

- Governance: Ensuring that the cloud provider has clear policies and procedures in place for data management, incident response, and risk management.

- Transparency: Making sure that the cloud provider is open and transparent about its operations, including its data center locations, ownership, and certifications.

By evaluating and managing the implications of transferring services to the cloud, businesses can build trust in their cloud computing services and feel confident that their data and systems are secure, compliant, and well-governed.

Additionally, businesses should also consider implementing their own internal policies and procedures to ensure that they are using the cloud services in a secure and compliant manner.

In summary, building trust into cloud computing is crucial for businesses as they transition their IT services to the cloud.

Hence, business’s should evaluate and manage the implications of transferring services to the cloud by considering security, compliance, governance and transparency.

Looking for End to End Industrial Automation & IoT Solutions?