How Industrial IoT Helps Companies Become Service Providers

Imagine you are trying to print your presentation for an important meeting, but your printer’s ink runs out during the process. You are not only losing precious time but your image as well.

Now imagine if your printer could inform you in advance of the left ink status and arrange for a refill much in advance? Convenient, isn’t it! That’s how some of the leading printer brands across the globe are now functioning, turning equipment manufacturers into service providers of products.

The changing economies across the globe; increased B2B and B2C expectations from companies, and increasing market competition – not just from existing counterparts but growing D2C and rental players – are pushing businesses to interact with consumers much beyond the sales cycle.

Through servitisation, the biggest trend to hit manufacturing since the internet, businesses are now associated with patrons throughout the life of the product, providing aftercare, tips, and even upgrades. And Industrial IoT (IIoT) is the key that is helping such companies by moving them closer to their customers.

Why must all companies be service providers?

Modern business models are designed to give consumers more power and control over their experiences and finances. Moreover, people are getting into the sharing economy, renting products rather than buying – right from home appliances and furniture, to automobiles.

Therefore, for manufacturers to stay in business and grow, it is all the more important than ever to offer consumers an experience beyond sales. Turning into service providers helps companies to do just that.

Sales is easier and customer acquisition costs become negligible if companies sell more services to their existing set of consumers, rather than pitching for new customers.

Keeping on touch with your user base is the goal.

Making a strong community out of your customers, solving pain points and creating product experiences where customers get to feel involved with the development of a product are a few points why companies pivot from Sales to building a brand and marketing.

If you are in the business of manufacturing Wind Turbines. Once you sell a Wind Turbine to an Energy company, your role in the sale is practically over, unless there are needs for repairs. Assumed depreciation of an asset over the years means your role as a product manufacturer is renewed only and after the existing product is deemed unusable or damaged beyond repair.

With the onset of the Fourth Industrial Revolution, we are exposed to more data on how our machines behave than we ever have been. We also have the right tools to analyze data, monitor situations, create a system of Alarms & Security and enable strategies that allow businesses to offer Just in Time services.

Understanding IIoT and its role in companies

IIoT or Industrial Internet of Things refers to the extension and use of the internet of things (IoT) in industrial sectors and applications. It has a big focus on machine-to-machine (M2M) communication, big data, and machine learning (ML) to enable industries and enterprises to have better efficiency and reliability in their operations.

IIoT stands at the distinct intersection of information technology (IT) and operational technology (OT) – referring to the networking of operational processes and industrial control systems (ICSs), including human machine interfaces (HMIs), supervisory control and data acquisition (SCADA) systems, distributed control systems (DCSs), and programmable logic controllers (PLCs).

IIoT goes beyond the normal consumer devices and internetworking of physical devices usually associated with Industrial Internet of Things and encompasses several industrial applications including the likes of robotics, medical devices, and several software-defined production and servicing entities.

How IIoT Can Help Your Company Become A Service Provider

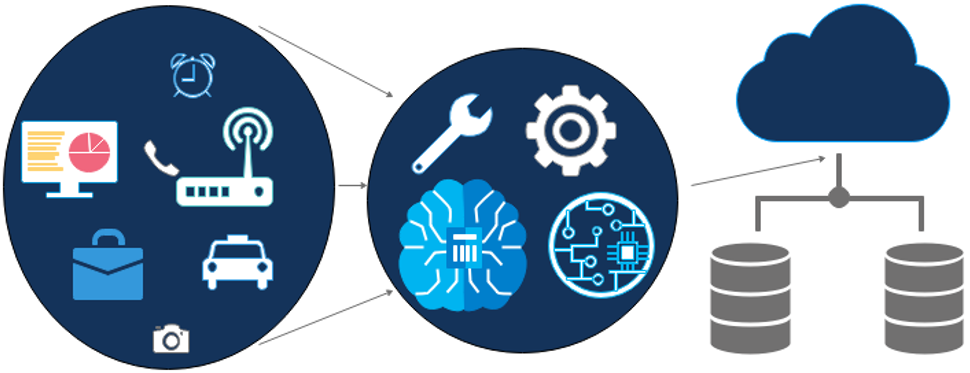

IIoT can serve multiple functions for companies in both manufacturing and servicing space. But its most important aspect for the latter is its use in data storage and assessment technology. The true value of the IIoT depends on how much quality data you can collect, analyze, and use.

IIoT is used to collect data via a network of sensors on systems or component parts. The data tracked gives the manufacturers relevant details on how a machine or product is operating, if there are any problems in its performance, and what is the user feedback and expectation.

As stated in the printer experience, the printer knows that it is running low on Ink. Cloud connected smart printers are frequent and can make decisions of directly purchasing ink from a listed vendor, there by reducing a customers hassle of manually buying an ink cartridge.

In essence, the concept of Industrial IoT or smart devices is creating a service that stretches through the product’s entire lifespan by collecting and analyzing data. It can be leveraged to inform your decisions at a tactical and strategic level. It improves the overall consumer experience by increasing operational efficiency by efficient scheduling, revealing bottlenecks for workflow optimization, and saving time in consumer communication.

Most importantly, data collected on the usage of a machine gives business’s valuable insights on how their products work, what are the points for wear and tear, and what are the customers pain points. Analyzing this data gives information on how we can better our products both in operational efficiency and improve a feeling of satisfaction of the customer.

Finding the right Industrial IoT Partner.

Finding the right partner to help you in your digitization journey is crucial. As a manufacturer, you are splendid at what you do, and your core competency is around the products that you manufacture. Diving into an area of digitization by yourself, and integrating systems with a connected network infrastructure might not be your best bet.

Embedos can be the one-stop solution for all these data collation and analysing needs for a company to turn into a service provider by providing hardware, software and cloud solutions based on your company’s targeted needs.

Its remote device configuration and firmware upgrade services can enhance the consumer experience and cloud visualization and analytics help manufacturers to keep a tab on product performance.

IIoT can change the way you do business and build long lasting relationships with your consumers in an efficient, cost effective and targetted manner.

Looking for End to End Industrial Automation & IoT Solutions?