How to calculate the service life of an industrial asset using Industrial IoT (IIoT)?

The service life of an industrial asset is the length of time that the asset can be expected to operate effectively and efficiently. There are several factors that can affect the service life of an industrial asset, including:

- The type of asset: Different types of assets have different expected service lives. For example, a piece of machinery may have a longer service life than a tool or a piece of equipment.

- The condition of the asset: The condition of the asset can have a significant impact on its service life. If an asset is well-maintained and operated correctly, it is likely to have a longer service life.

- The environment in which the asset is used: The environment in which an asset is used can also affect its service life. For example, an asset used in a harsh or corrosive environment may have a shorter service life than an asset used in a more benign environment.

- The level of use: The more an asset is used, the shorter its service life is likely to be.

To calculate the service life of an industrial asset, you will need to consider these factors and make an educated estimate based on your specific circumstances. You may also want to consult industry standards or guidelines for guidance on expected service life for different types of assets.

There are a few other factors that can impact the service life of an industrial asset:

- The quality of the asset: Higher quality assets are likely to have a longer service life than lower quality assets.

- The level of maintenance: Regular maintenance can help extend the service life of an asset by ensuring that it is operating correctly and efficiently.

- The design of the asset: The design of an asset can also impact its service life. For example, an asset designed with durability in mind is likely to have a longer service life than an asset designed for lower cost.

- The level of expertise of the operators: The level of expertise of the operators can also affect the service life of an asset. If operators are trained to operate the asset correctly and are familiar with best practices, it is likely to have a longer service life.

- The availability of replacement parts: The availability of replacement parts can also impact the service life of an asset. If it is difficult to obtain replacement parts, the service life of the asset may be shorter.

It is important to carefully consider these factors when calculating the service life of an industrial asset, as they can have a significant impact on the overall performance and reliability of the asset.

How does industrial iot play a role in this ?

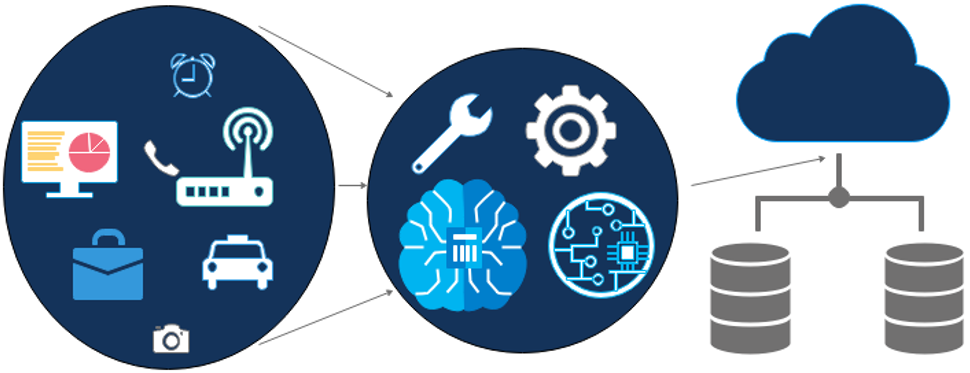

Industrial Internet of Things (IIoT) refers to the use of connected devices and sensors to gather and analyze data in industrial settings. In terms of calculating the service life of an industrial asset, IIoT can play a role in several ways:

- Monitoring asset performance: IIoT devices can be used to monitor the performance of an asset in real-time, allowing you to identify problems or issues before they become major issues. This can help extend the service life of the asset by allowing you to address problems as they arise.

- Improving maintenance practices: By gathering data on the performance and usage of an asset, IIoT can help identify when maintenance is needed and what type of maintenance is required. This can help ensure that the asset is properly maintained and extend its service life.

- Identifying patterns of failure: By analyzing data over time, IIoT can help identify patterns of failure that may indicate that an asset is reaching the end of its service life. This can allow you to plan for replacement before the asset fails completely.

- Predictive maintenance: IIoT can be used to predict when an asset is likely to fail or need maintenance, allowing you to schedule maintenance in advance and avoid unexpected downtime.

- Reduced downtime: By identifying problems before they become major issues, IIoT can help reduce downtime and improve the overall efficiency of an industrial operation.

Overall, IIoT can play a significant role in helping to extend the service life of industrial assets by providing the data and insights needed to optimize asset performance and maintenance.

However, there are also some potential cons to using IIoT for asset maintenance:

Cons:

- Cost: Implementing IIoT can be expensive, as it requires the purchase and installation of sensors and other equipment.

- Complexity: Managing and analyzing data from IIoT devices can be complex and time-consuming, requiring specialized skills and expertise.

- Security risks: IIoT devices can be vulnerable to hacking and other security threats, which can potentially compromise the security and integrity of an industrial operation.

Overall, the decision to use IIoT for asset maintenance will depend on the specific needs and goals of an industrial operation, as well as the available resources and budget. It may be worth considering the potential pros and cons carefully before implementing IIoT in order to ensure that it is the right fit for your operation.

How can we implement industrial iot in a cost effective manner for better asset health and calculate service life

There are several steps you can take to implement Industrial Internet of Things (IIoT) in a cost-effective manner in order to improve asset health and calculate the service life of industrial assets:

- Identify the assets that will benefit most from IIoT: Not all assets will benefit equally from IIoT, so it is important to identify the assets that are most critical to your operation and will benefit most from IIoT monitoring and analysis.

- Determine what data is most important to collect: Collecting data can be expensive, so it is important to determine what data is most important to collect in order to optimize asset performance and maintenance.

- Use existing infrastructure: If possible, try to use existing infrastructure, such as network and data storage systems, to reduce the cost of implementing IIoT.

- Use open-source or low-cost hardware and software: There are many open-source and low-cost options available for IIoT hardware and software, which can help reduce the overall cost of implementing IIoT.

- Use a phased approach: Instead of trying to implement IIoT across an entire operation all at once, consider a phased approach that allows you to gradually roll out IIoT and test its effectiveness before expanding it further.

- Utilize existing expertise: If you have staff with relevant skills and expertise, consider leveraging their knowledge to help implement and manage IIoT.

By following these steps, you can help ensure that you are implementing IIoT in a cost-effective manner that helps optimize asset performance and maintenance, and improve the accuracy of service life calculations.

Looking for End to End Industrial Automation & IoT Solutions?