Embedos can help multiple Tank Manufacturers and Dairy Producers alike by providing an integrated solution to optimize on Tank Fill Control.

Overfilling tanks in liquid manufacturing industries is a major concern; it can not only lead to business losses but can also be a great safety hazard in several industries. It may also lead to potentially severe consequences if the fluid is flammable or environmentally sensitive.

Along with all this, maintaining a safe level of liquid in tanks is necessary to preserve the mechanical industry of tanks. Therefore, it is very important for tank manufacturers and industries like dairy producers to have a robust and technically advanced tank fill control system in place.

Importance of tank fill control in industries

Liquid storage tanks require careful monitoring and maintenance of liquid levels to ensure optimal productivity in industries. By ensuring that the tanks never run empty, you can increase your production. And preventing overflowing will save time, money, and efforts by the workforce. Having the right levels of liquid stored in the system also increases tank life and performance.

Liquid level controllers are mechanical devices used to integrate a 2-way sensing system that senses the fluid at the top and the bottom of the tank or the water structure. This way you can keep a constant check on both when the liquid is overfilled or less filled to optimise the tank performance and increase productivity and production in your units.

Why choose Embedos EB Series?

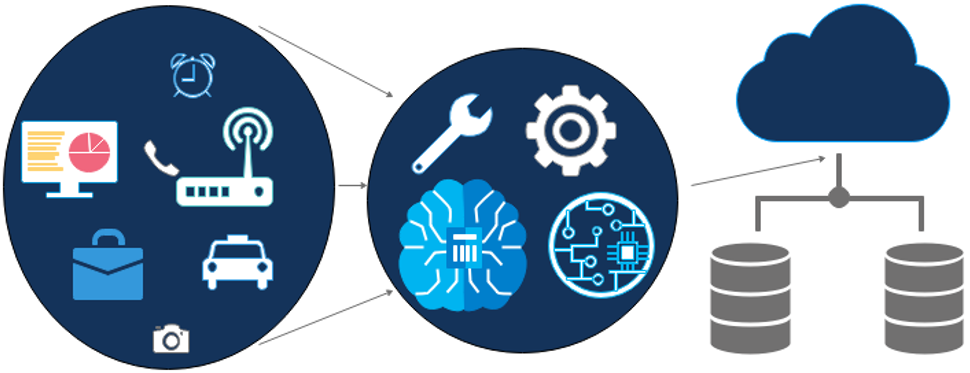

A technically-advanced controller that works on real-time data and system integrations can solve a lot of trouble. Embedos EB Series (EM Bose) is currently amongst the best liquid-level controllers for tank manufacturers & liquid production industries like dairy, water, juice, oil, wine etc when it comes to measuring the level of multiple liquids without changing device configuration.

Combining with Temperature Input interfaces on Thermocouple / RTD inputs, the same controller can measure & display liquid level and temperature of the environment / tank.

Compatible with both vertical and horizontal tanks, EM Bose is a tested and heavily deployed industrial solution. It calculates the volume of the liquid in the tank taking inputs from a pressure sensor mounted at the bottom of the tank. The data collected on the volume is displayed in real-time via a digital screen.

The process is maintained over a Wifi interface. This interface is able to receive Over the Air (OTA) updates if there is a requirement to upgrade the application over the internet.

Em Bose – The liquid level controller allows users to set threshold limits between which the liquid of interest is to remain. If the liquid crosses either of the two set points, the device sets off a relay which is connected to a high wattage industrial lamp to indicate that the threshold has been crossed.

The device is also contains a built in buzzer that goes off as soon as the liquid crosses the threshold points. The user can physically acknowledge or disable this buzzer based on the operator’s choices.

Interesting features of the Embedos EB Series EM Bose include its compatibility in systems hosting changing densities of liquids at the same time. Liquids with different densities can be filled in the tank at a time, and the device internally calculates the volume of the liquid based on the relative density of the liquid.

At a time, only one liquid can be filled in a tank. Since water has a different density than Oil, Milk, syrup & wine, no additional changes are to be done with the measuring equipment. The Em Bose will internally handle all densities, calculate the liquid of Interest’s Volume and accordingly give us the desired Liquid level on the Touchscreen display.

Density is a metric of weight and can be calculated by how much force the liquid exerts per unit area also called pressure.

Density is an essential factor to consider when it comes to liquid packaging since it affects the speed with which the liquid travels through the pipe, sets, dries, and is dispensed into the packaging. That’s why it is important to measure density accurately.

Which industries can benefit from Embedos EB Series

There are a lot of industries that deal with the production and supply of fluids and Embedos EB Series is a perfect fit for all. While tank manufacturers can directly use it to equip their products with high-end technical expertise, industries that are using simple tanks can also get the Embedos EB Series controllers installed.

When it comes to water, it can be used in an open well, bore well, sumps, single-phase motors, and three-phase motors. Industrial Sewage Tanks, Dairy Tanks, Syrup Tanks, Fruit Juice Tanks, Wine Cellars & Vineyards, Oil Tanks, Water Tanks, or any vertically / horizontally positioned tank that requires a liquid to be stored inside is an application area of these controllers.

Further, in most oil drilling operations, crude oil pumped directly from the borehole is mixed with water, gases, and sand to separate in a special tank. Embedos EB Series is compatible with such systems as it can calculate the levels of different liquids based on different densities at the same time.

These fluid level controllers are a must in the breweries as well where Greater or lesser quantities of water and mash produce different qualities in the final product, and accurate level switches can ensure that storage containers don’t overflow. Similarly, it is a great fit for fruit juice manufacturers.

Therefore, multiple industries, including the dairy industry, fruit juice manufacturers, wine breweries, or even building water tanks can use this solution for exact fluid level controls.

Check out the application + USer Manual Here.

Looking for End to End Industrial Automation & IoT Solutions?