The Language of Machines: A CAN Bus Journey

The Silent Symphony

Dawn broke over the city as Maya stepped out of her apartment building. The streets were quiet, save for the occasional hum of a passing car. She checked her watch; 6:30 AM. Perfect timing. Her friend Ethan would be arriving any minute for their road trip.

“Right on schedule,” Maya thought as Ethan’s silver sedan pulled up to the curb. She tossed her backpack into the trunk and slid into the passenger seat.

“Morning, Professor,” she teased, knowing how much Ethan loved explaining the inner workings of cars to anyone who would listen.

“Morning, Maya,” Ethan grinned, tapping the dashboard affectionately. “Ready for a little adventure?”

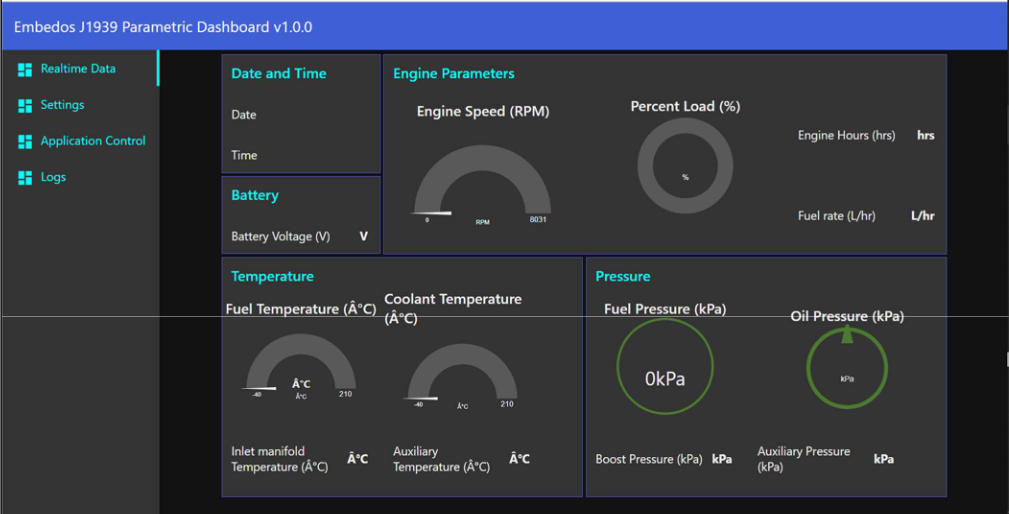

As they pulled away from the curb, Maya noticed the dashboard light up with colorful displays navigation, climate control, engine status, all working in perfect harmony.

“It’s amazing how everything just… works together,” she mused, gesturing at the dashboard. “How does your car know to do all these things at once?”

Ethan’s eyes lit up. There was nothing he loved more than a chance to explain automotive technology.

“That, my friend, is the magic of CAN Bus.

The Birth of a Language

“CAN what now?” Maya raised an eyebrow.

Controller Area Network Bus, Ethan replied, guiding the car onto the highway. “It’s like… imagine if all the systems in this car needed to talk to each other, but they all spoke different languages.”

“Sounds chaotic,” Maya laughed.

“Exactly! Back in the day, that’s exactly how it was. Each system – the engine, brakes, airbags – they all had their own wiring and couldn’t easily communicate. It was a mess of wires and complexity.”

Maya glanced at the sleek interior of the modern car. “Obviously, that’s changed.”

“In 1986, a company called Bosch changed everything,” Ethan continued, his voice taking on the quality of a storyteller. “They created CAN Bus, essentially a universal language and communication highway for all electronic components in a vehicle.”

As they drove, Ethan told Maya how before CAN Bus, cars were simple creatures with basic needs. A few wires, an engine, and mechanical parts were all they required. But progress demanded more sophisticated engines, safety systems, entertainment features and with this complexity came a problem: communication.

“Think about it like this,” Ethan said as they stopped at a red light. “Imagine if every person in a city could only talk to one other person through a dedicated phone line. You’d need millions of phone lines crisscrossing everywhere!“

“That sounds inefficient and messy,” Maya replied.

“Exactly! That’s what car wiring was like before CAN Bus. But CAN Bus is like giving everyone in that city access to a group chat. Now, every system can communicate over the same network, sharing one communication line. One wire replaced hundreds.”

The Highway of Data

As they merged onto the interstate, traffic began to pick up. Cars jockeyed for position, some speeding ahead while others maintained their pace in adjacent lanes.

“See this highway?” Ethan gestured through the windshield. “This is exactly how the ‘Bus’ in CAN Bus works.”

Maya watched the ebb and flow of traffic with new interest.

“The ‘Bus’ is just a communication pathway,” Ethan explained. “Like this highway, it allows multiple ‘vehicles’ of data to travel together. Some messages are more important than others – they’re like ambulances with sirens blaring, getting priority over regular traffic.”

“So when you hit the brakes…” Maya began.

“Exactly!” Ethan’s face lit up. “When I press the brake pedal, a high-priority message rushes down the CAN Bus highway, telling multiple systems: ‘Hey! We’re stopping!’ The brake lights receive the message and illuminate. The anti-lock brake system activates if needed. The engine adjusts its power. All these conversations happen in milliseconds over a single pathway.”

Maya watched as Ethan changed lanes smoothly, the car responding to his commands instantly. “It’s like an orchestra,” she mused.

“The perfect metaphor,” Ethan nodded appreciatively. “CAN Bus is the conductor, ensuring every instrument plays exactly when it should.”

When Messages Matter Most

About an hour into their journey, a truck ahead of them suddenly slowed. Ethan had been explaining the finer points of error correction in CAN Bus communication when his car’s collision warning system beeped sharply.

The car responded instantly – reducing speed, tightening seatbelts, and preparing the brake assist system – all before Ethan had fully registered the danger.

“That,” he said after they had safely changed lanes, “was CAN Bus in action when it matters most.”

Maya looked impressed. “All those systems reacted at once.”

“And in the right order,” Ethan added. “That’s the beauty of the priority system. The most critical safety messages get through first. If two systems try to send messages simultaneously, the one with the highest priority – usually safety-related – gets through first.”

“What if there’s an error in the message?” Maya asked, intrigued now.

“CAN Bus has that covered too. It’s like sending a text message with a built-in spell checker. If a message gets corrupted during transmission, the system detects it and requests a retransmission. For critical systems, that can happen multiple times per second.”

The Birth of a Revolution

As they stopped for coffee at a roadside diner, Ethan continued his story, telling Maya about the origins of this revolutionary technology.

“Picture this: It’s the early 1980s. Engineers at Bosch are struggling with the growing complexity of vehicle electronics. They need a solution that’s efficient, reliable, and flexible.”

Maya sipped her coffee, genuinely interested now. “So they created CAN Bus?”

“They did. The development started in 1983, and by 1986, they presented it at the Society of Automotive Engineers (SAE) conference. It was revolutionary – a communication protocol specifically designed for vehicles where reliability is literally a matter of life and death.”

“When did it become the standard?” Maya asked.

“It took time,” Ethan replied. “The first CAN controller chips were released in 1991 by Intel and Philips. By 1993, it became an international standard – ISO 11898. Then in 1996, it became mandatory for OBD-II diagnostic systems in all vehicles sold in the United States.”

“So every car on the road uses this now?”

“Most modern ones do. And not just cars , it’s used in factory equipment, medical devices, even some spacecrafts! What started as a solution for automotive complexity became a universal language for all kinds of machines.”

Beyond the Road

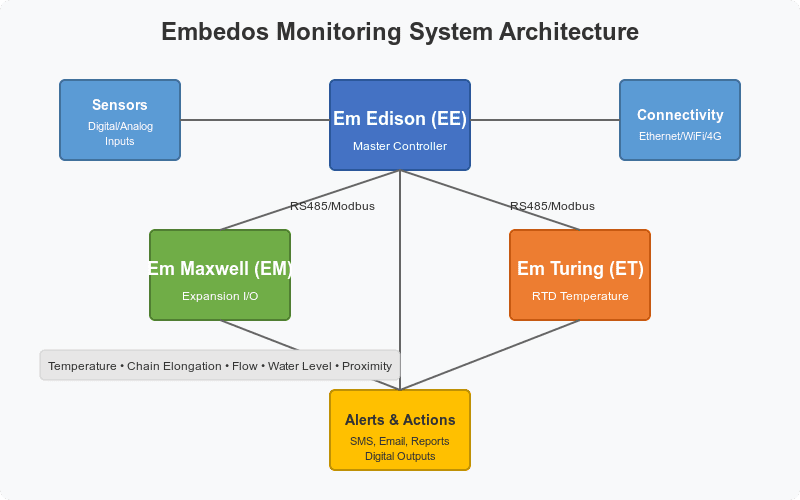

Back on the highway, their conversation drifted to other applications of CAN Bus technology. Ethan explained how the same principles that keep cars safe are now being applied in surprising places.

“Those wind turbines we passed earlier? Many use CAN Bus to coordinate blade pitch and monitor performance. The farm equipment in those fields? CAN Bus helps coordinate harvesting operations.”

“What about new technologies like electric vehicles?” Maya asked.

“Even more critical there,” Ethan replied enthusiastically. “In EVs, CAN Bus manages battery systems, monitors charging, and coordinates power distribution. It’s the nervous system that makes electric mobility possible.”

As they approached their destination in the late afternoon, Maya looked at the dashboard with new appreciation.

“I never realized there was this whole conversation happening inside the car,” she said. “It’s like discovering there’s a hidden orchestra playing all around you.”

Ethan smiled. “That’s what I love about technology like CAN Bus. It’s invisible, humble even – working silently in the background. But without it, none of our modern transportation would be possible.”

The sun began to set as they pulled into the hotel parking lot, casting long shadows across the asphalt.

“Is that the end of the CAN Bus story?” Maya asked as they unloaded their luggage.

Ethan laughed. “Not even close. With autonomous vehicles, smart cities, and connected transportation, we’re just beginning a new chapter. The language of machines will keep evolving, but CAN Bus laid the foundation – creating a world where our vehicles are no longer just collections of parts, but orchestrated symphonies of technology.”

“All because someone needed to solve a wiring problem,” Maya mused.

“Sometimes,” Ethan replied, “the most revolutionary ideas start by solving the simplest problems.“

As they walked toward the hotel entrance, the car’s lights flashed once, a symphony of systems saying goodnight, speaking in the silent language of CAN Bus.